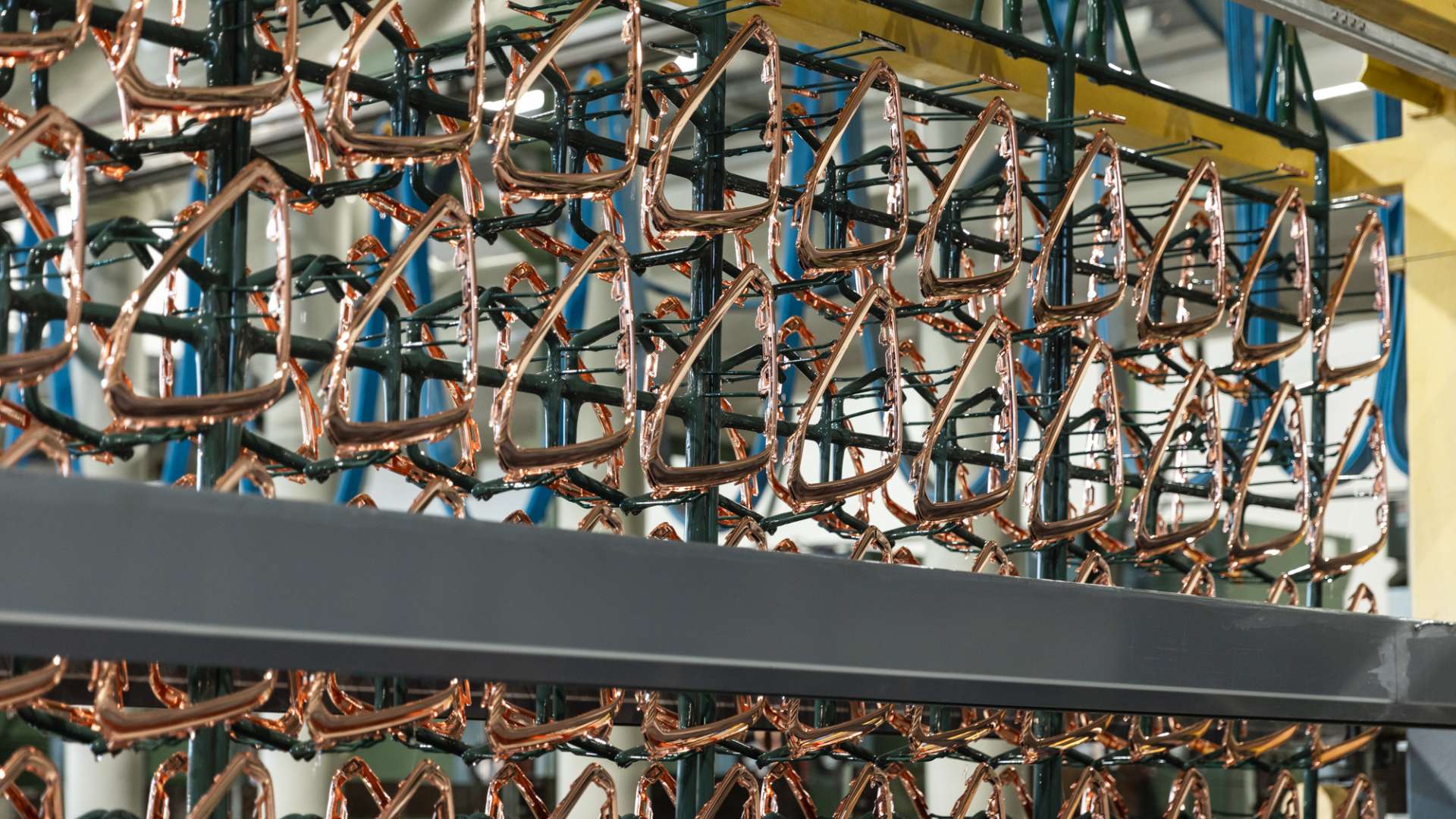

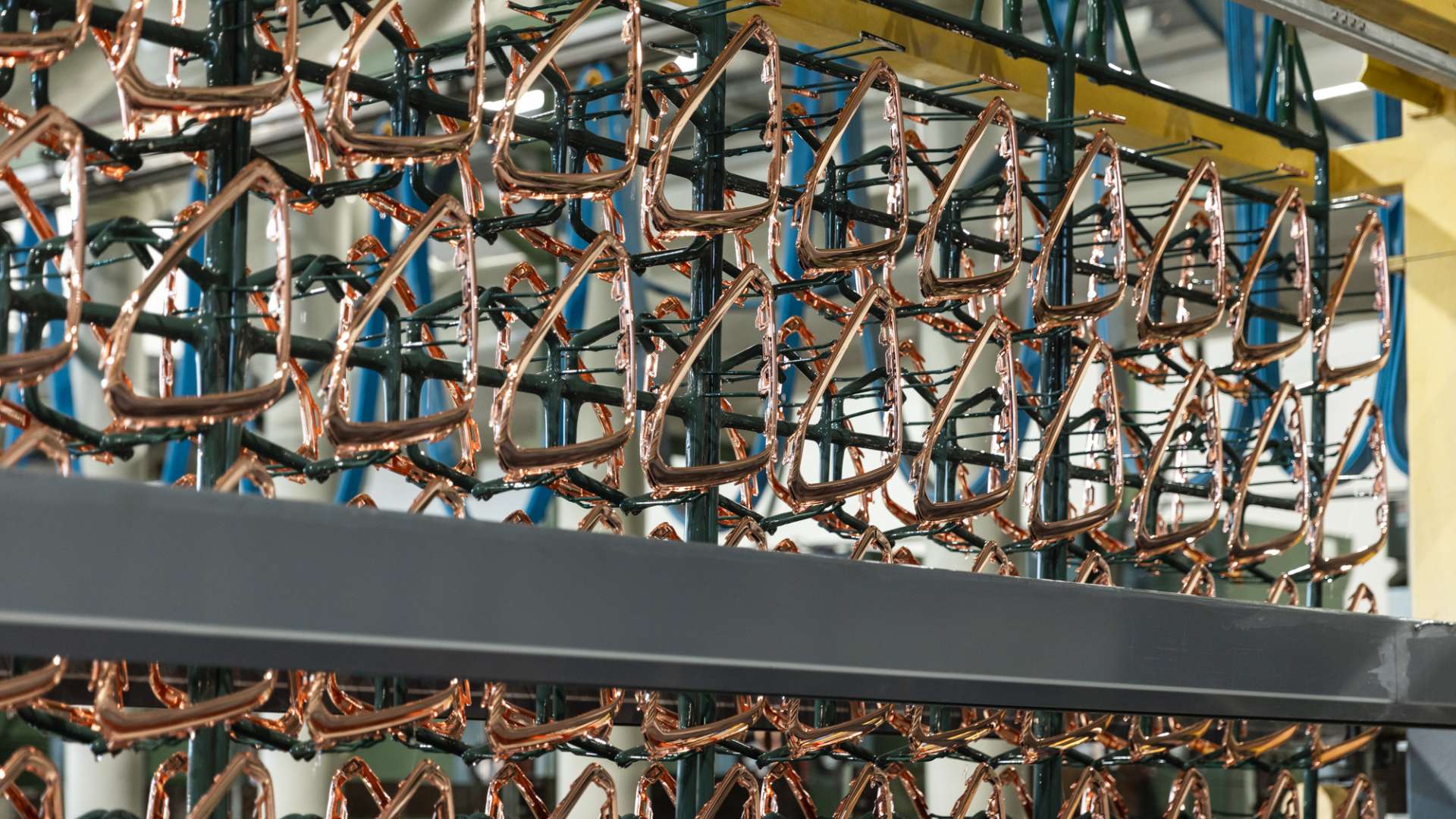

At the heart of our production lies an unwavering commitment to quality and efficiency. We utiliz cutting-edge machinery, rigorous quality controls and optimized processes to ensure that every product that leaves our factory is a testament to our excellence. We are ready to meet the most demanding requirements and deliver products that exceed expectations.

Our manufacturing service is designed to offer high-quality plastic solutions, crafted with an unwavering dedication to perfection. Our production process is characterized by a constant commitment to excellence, evolution, and customer satisfaction. We take pride in offering high-quality products that reflect our dedication to perfection in every detail.

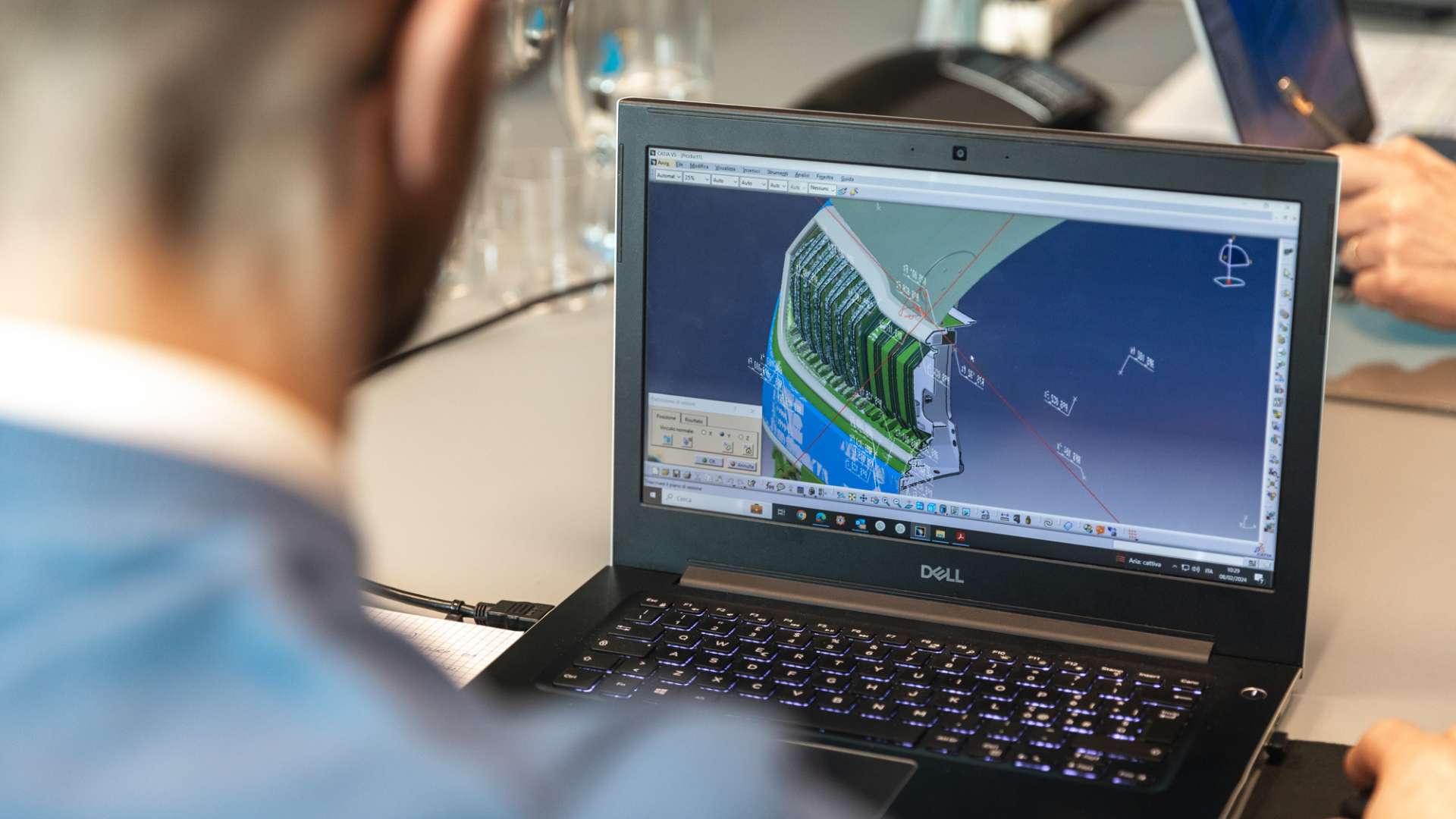

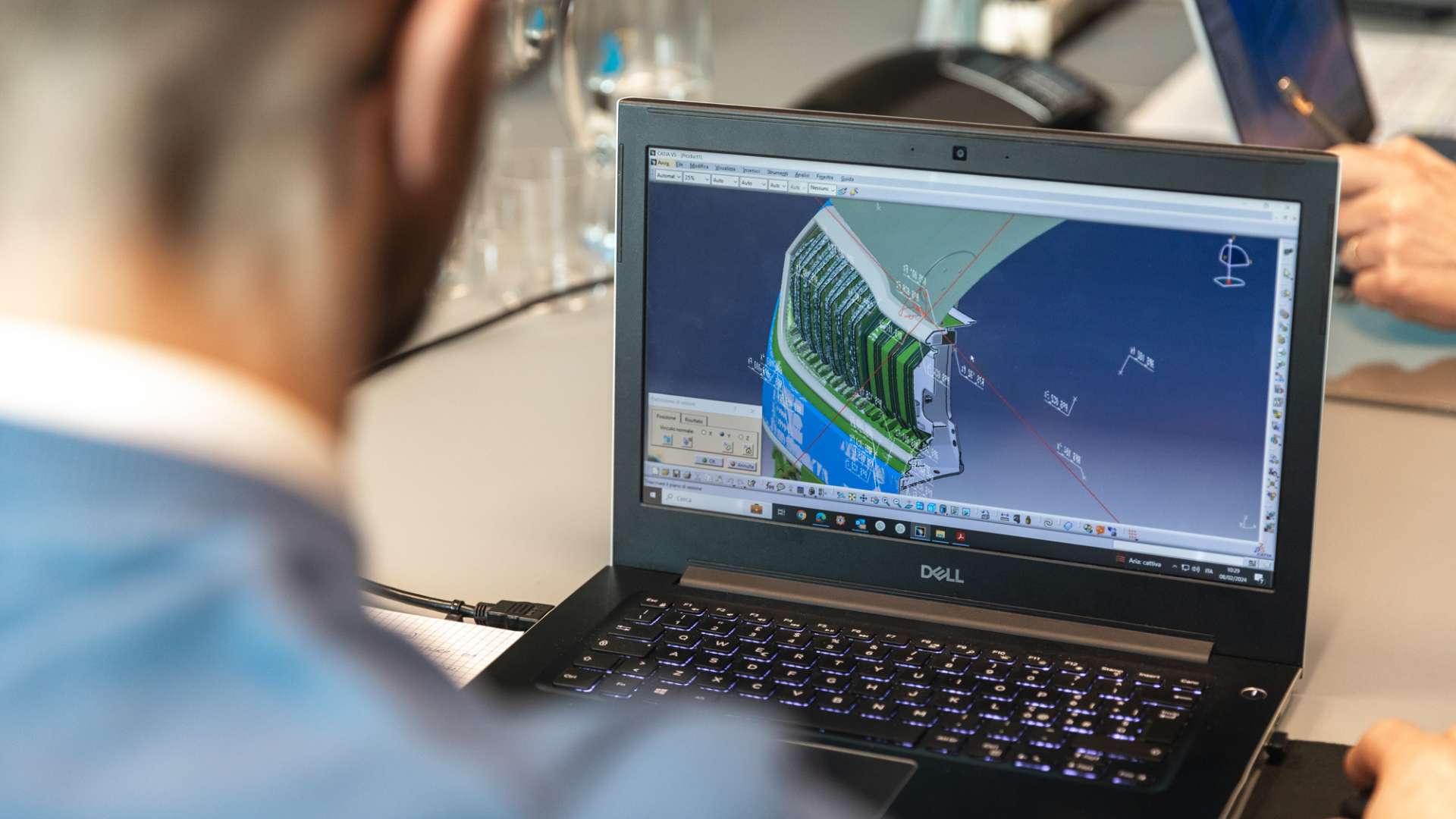

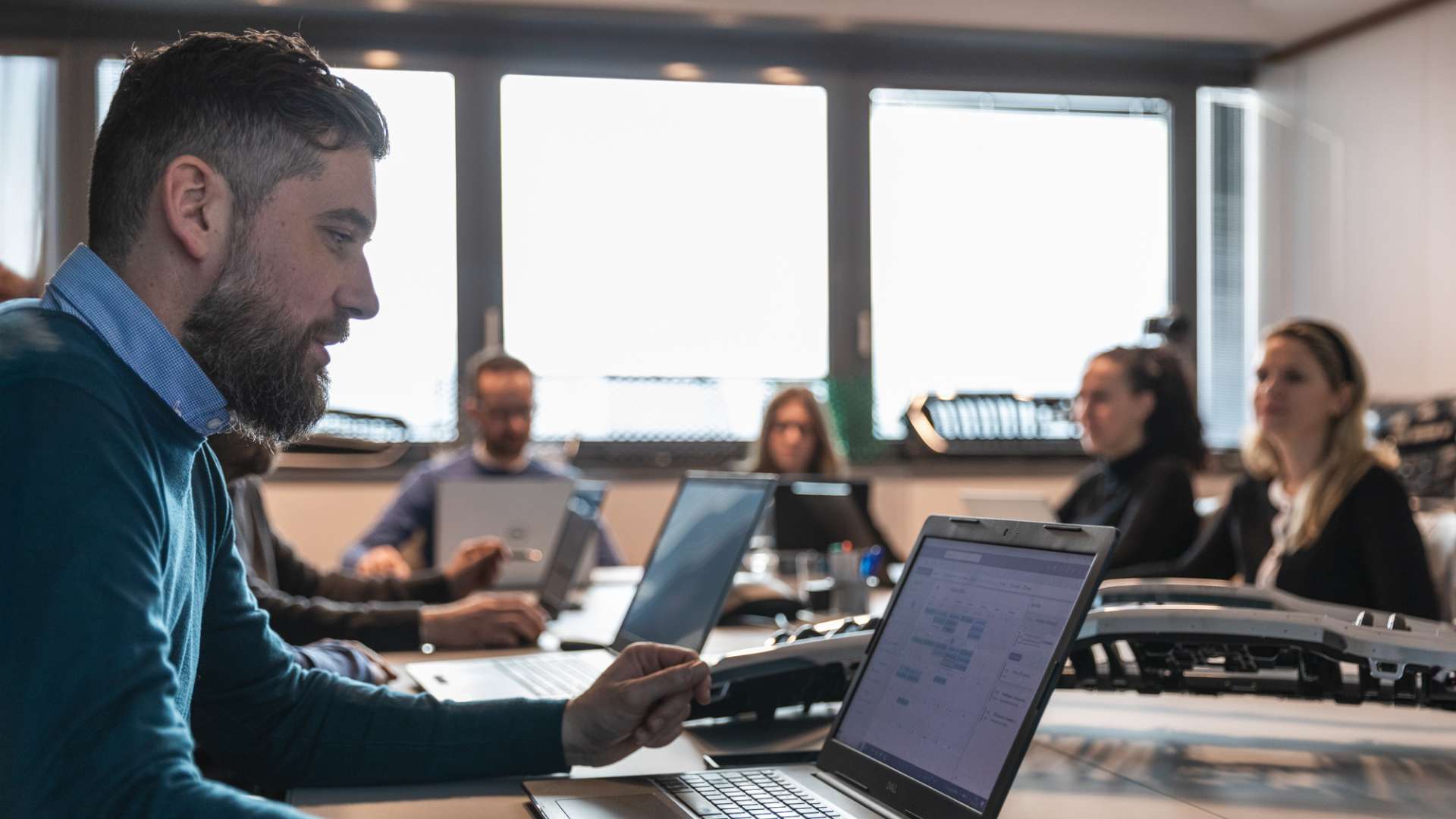

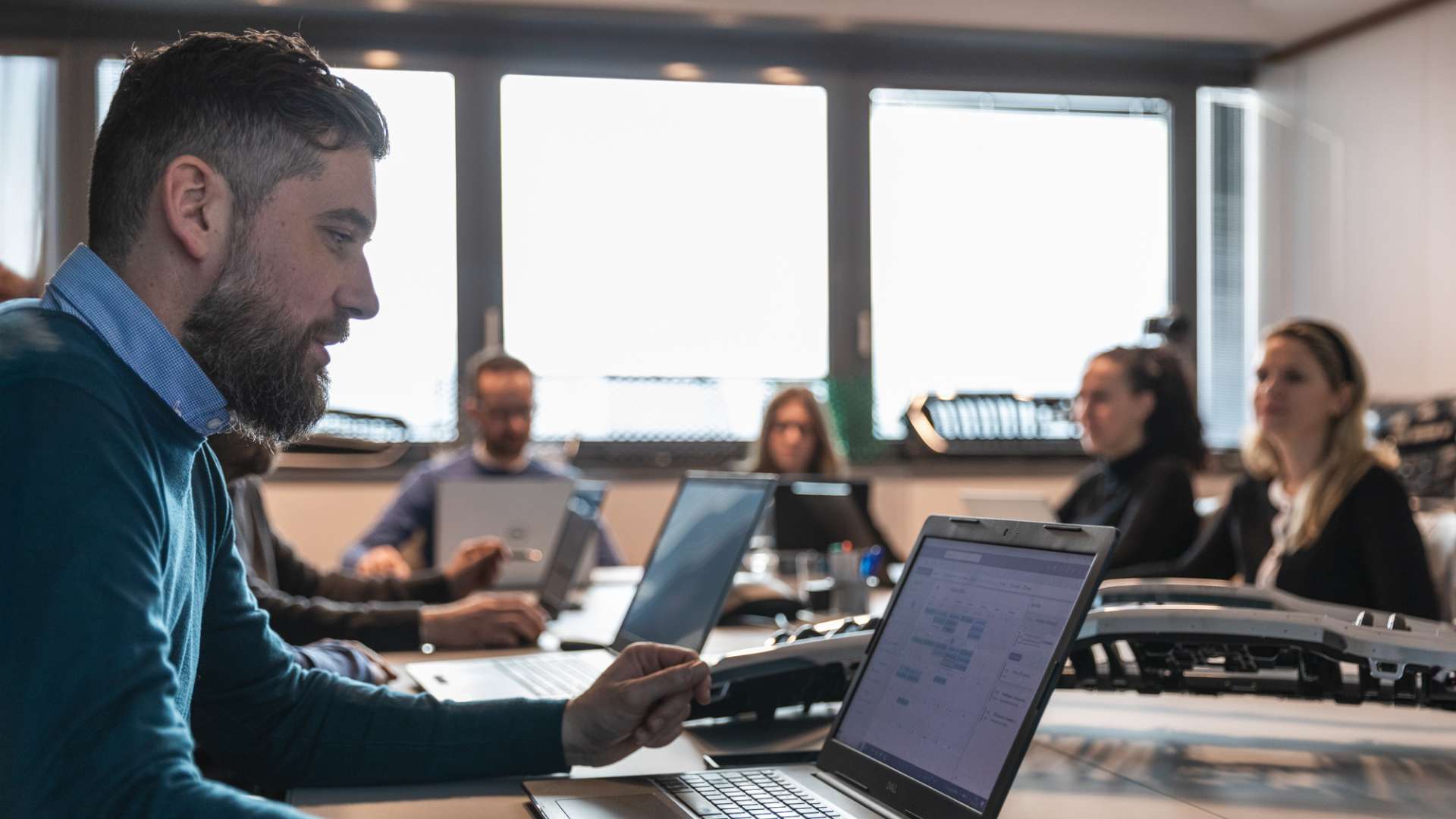

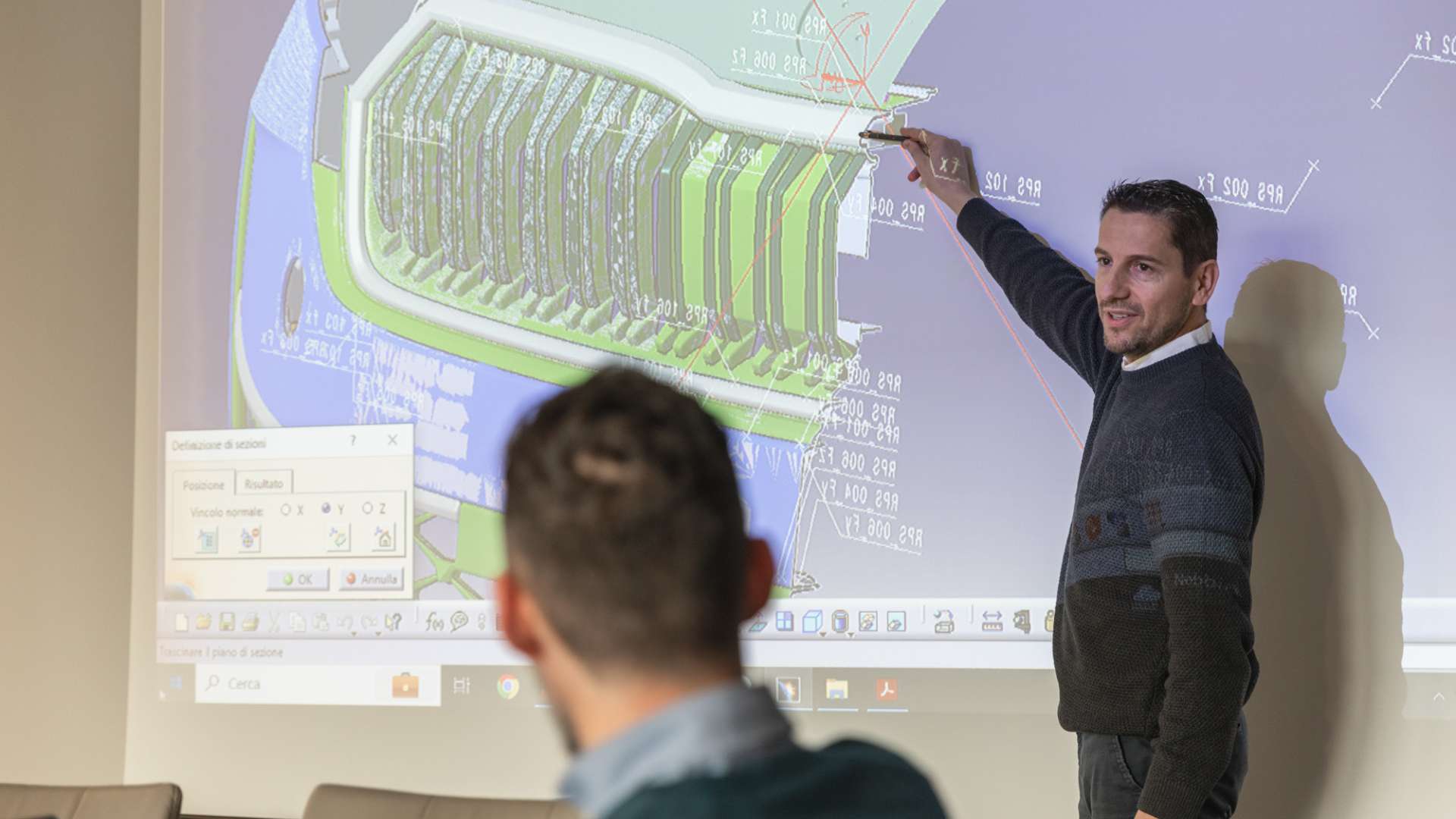

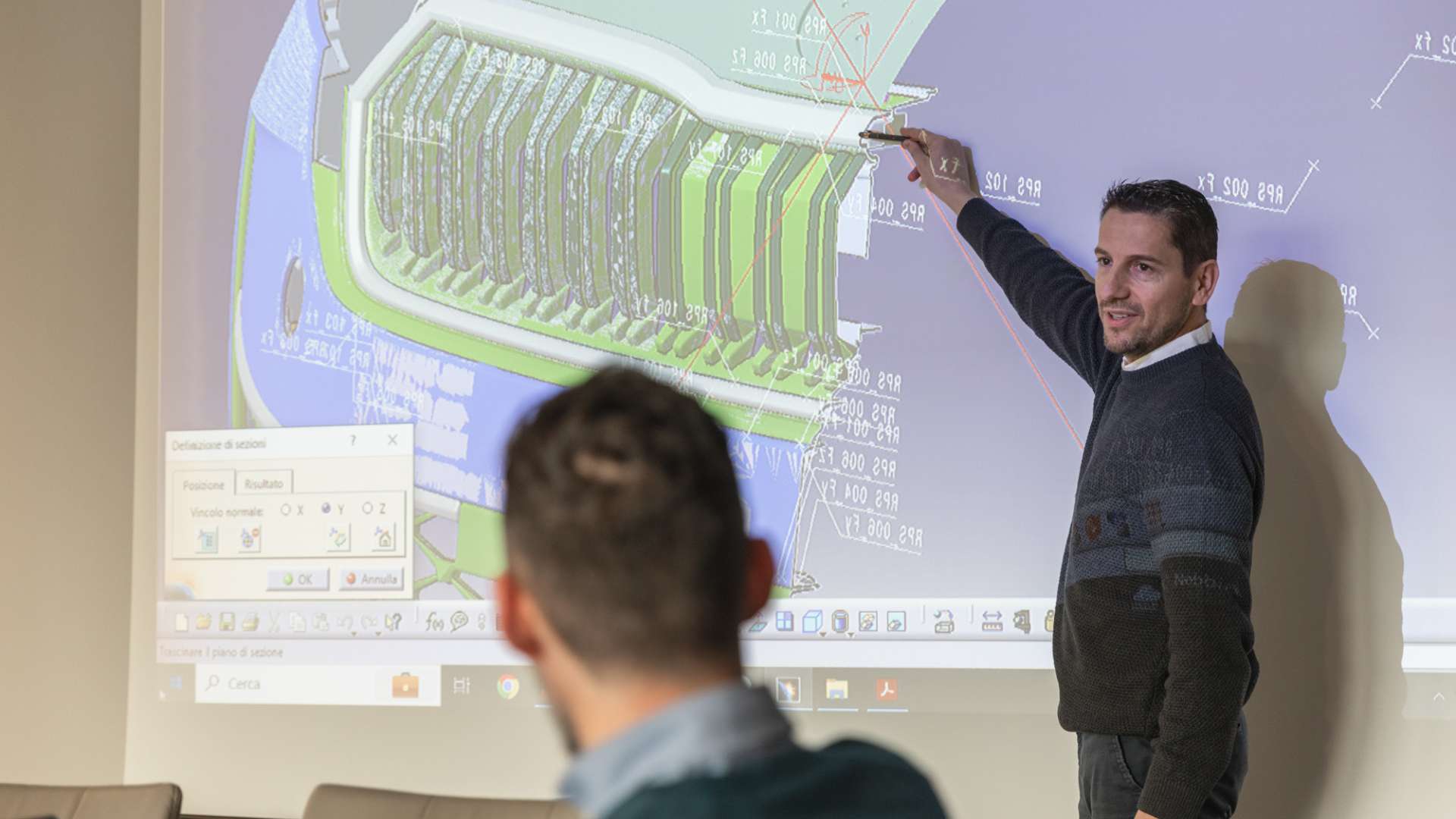

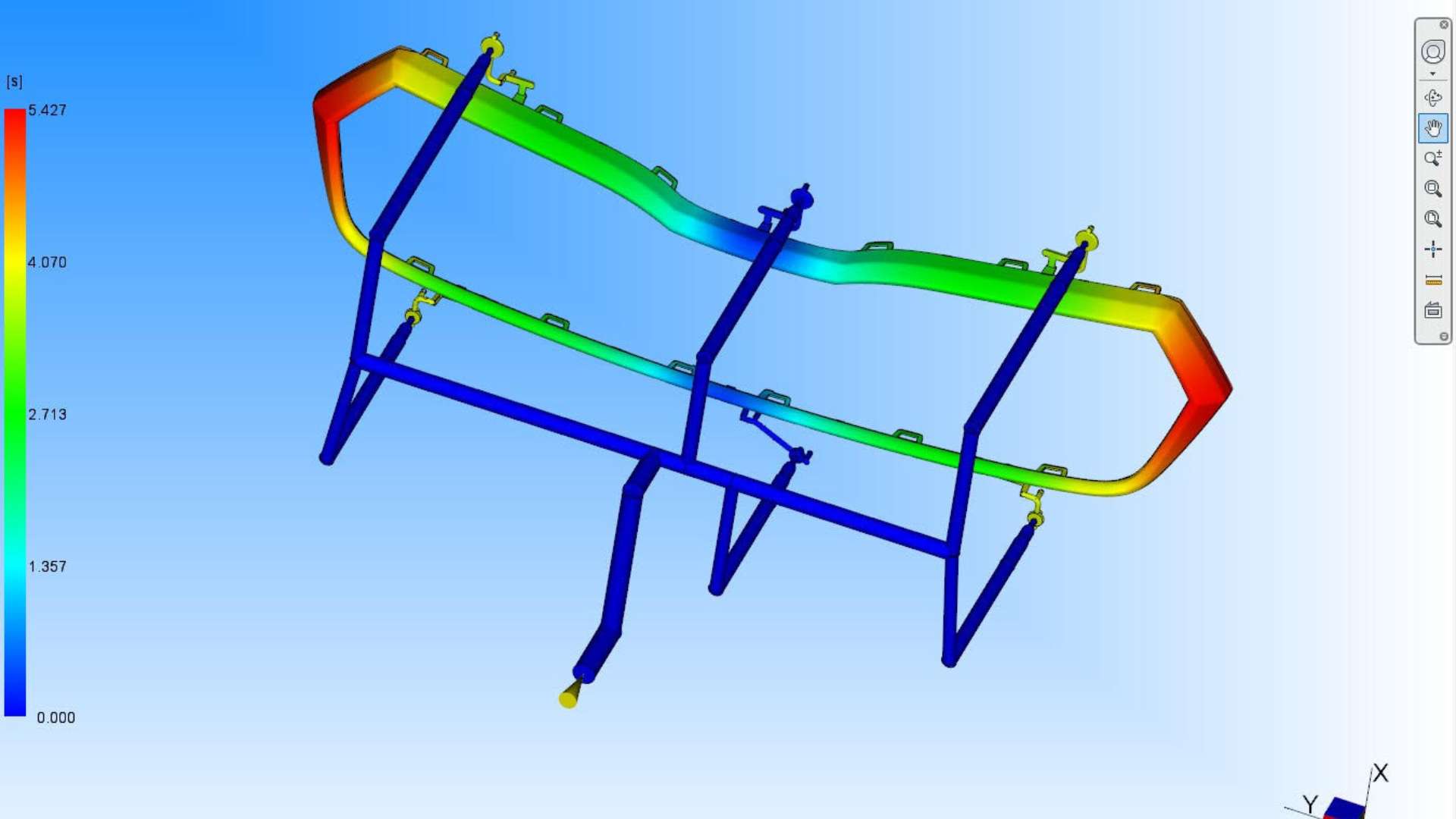

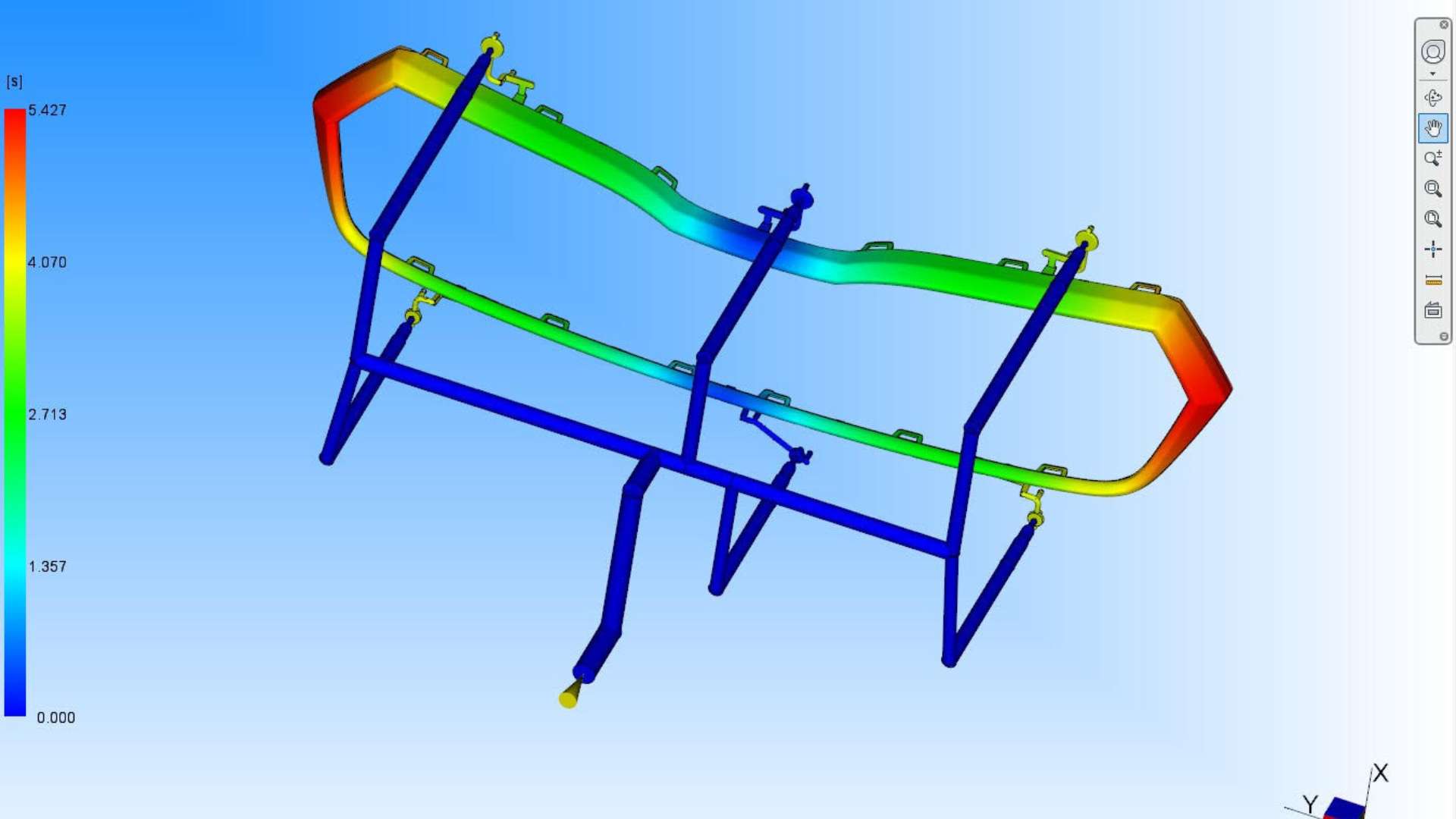

Our development service embraces the challenge of turning ideas into tangible products. We utiliz cutting-edge technologies, advanced simulations and a multidisciplinary approach to ensure that every phase of the development process is flawless. We collaborate closely with customers, constantly refining the small details to ensure a final result that exceeds expectations.

We also conduct feasibility studies, FMEA (Failure Modes & Effect Analysis) of products and/or processes, and sintered prototypes.

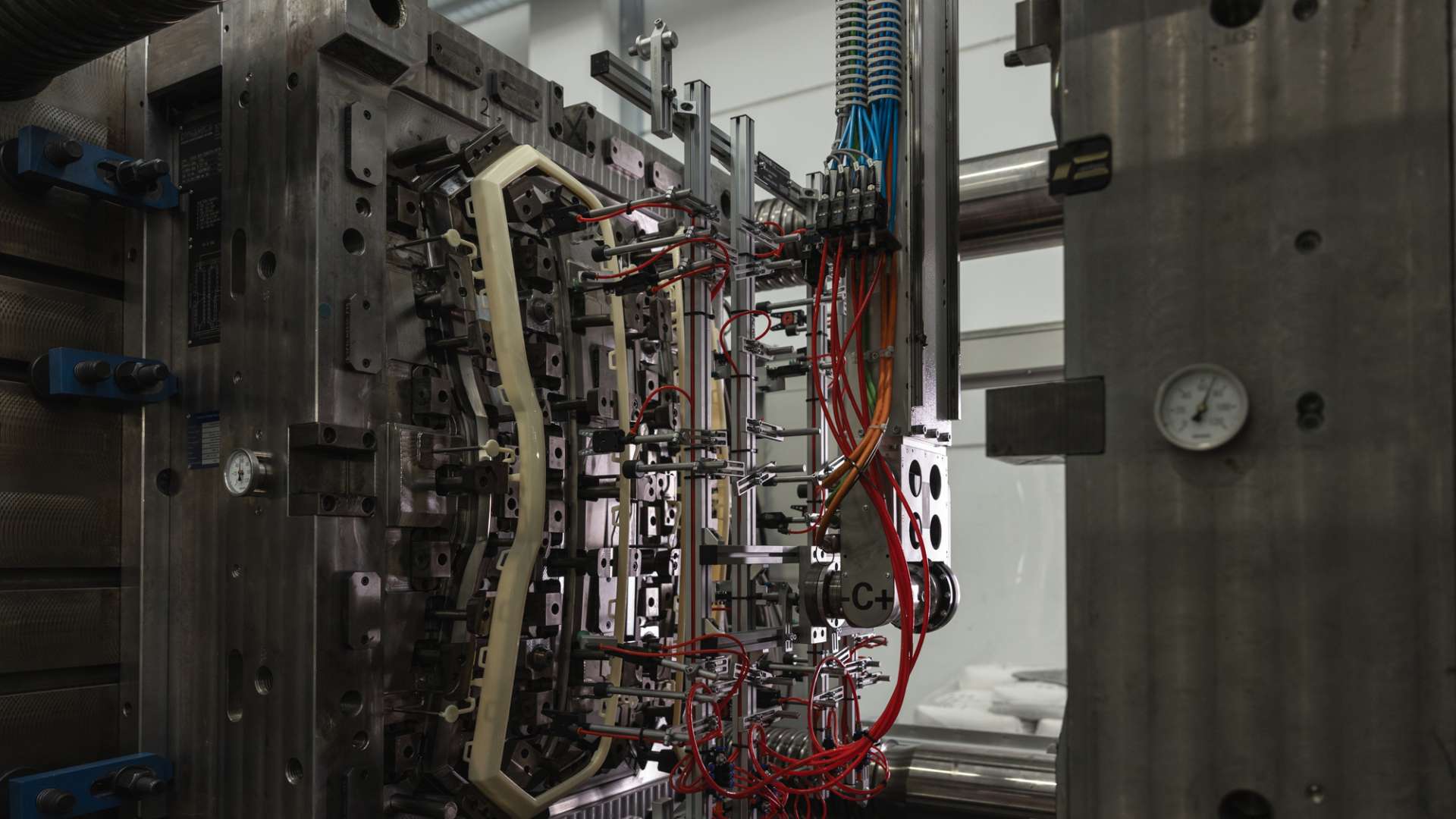

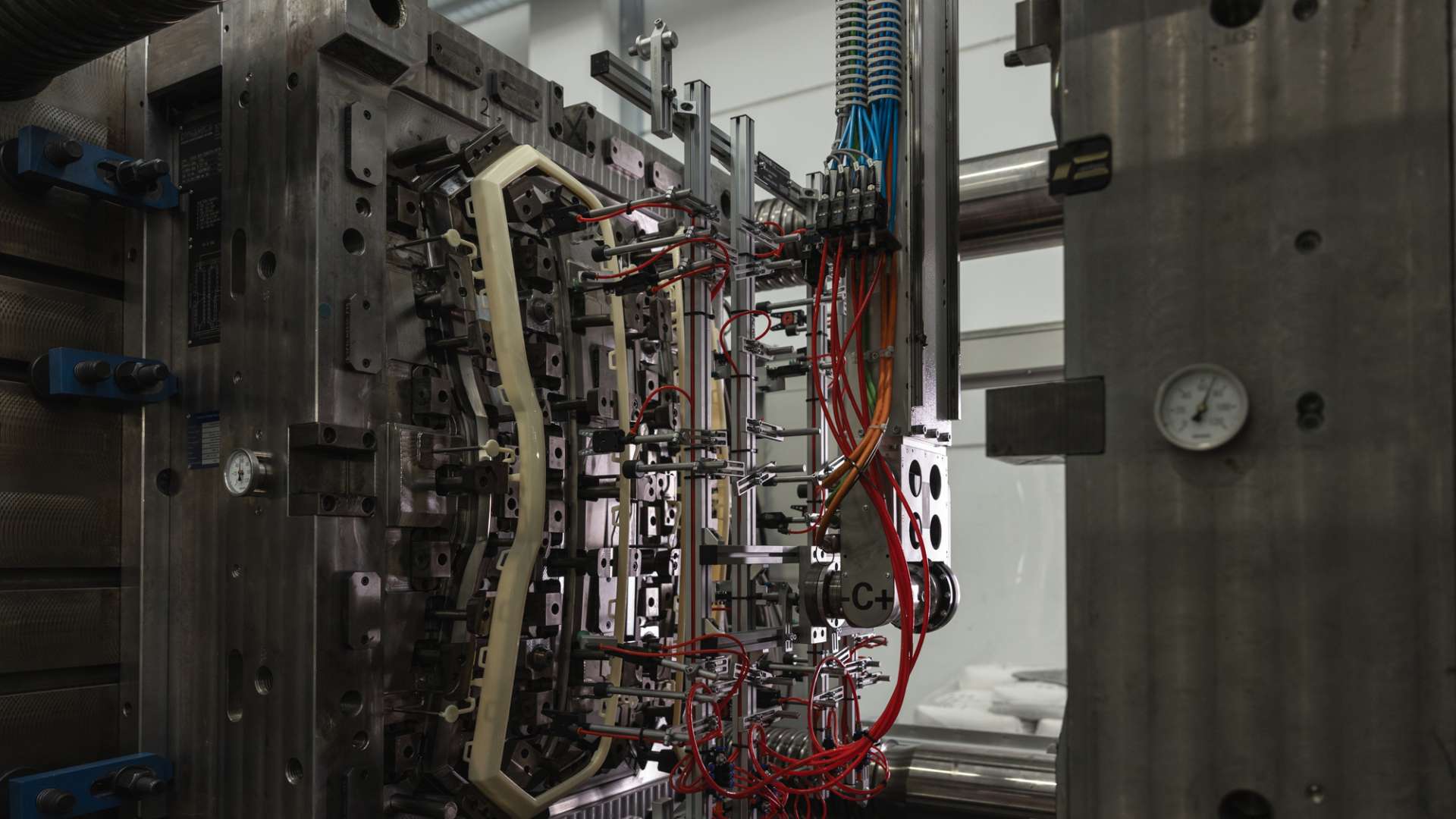

We use advanced design technologies and are meticulous when it comes to the attention to detail in the use of customized molds that precisely meet project specifications. This service positions us at the forefront of the industry.

Qualified manufacturers are available to produce injection molds, and we oversee the setup from start to finish to achieve the highest technical/aesthetic results in terms of customer satisfaction, cost containment, and product realization times.

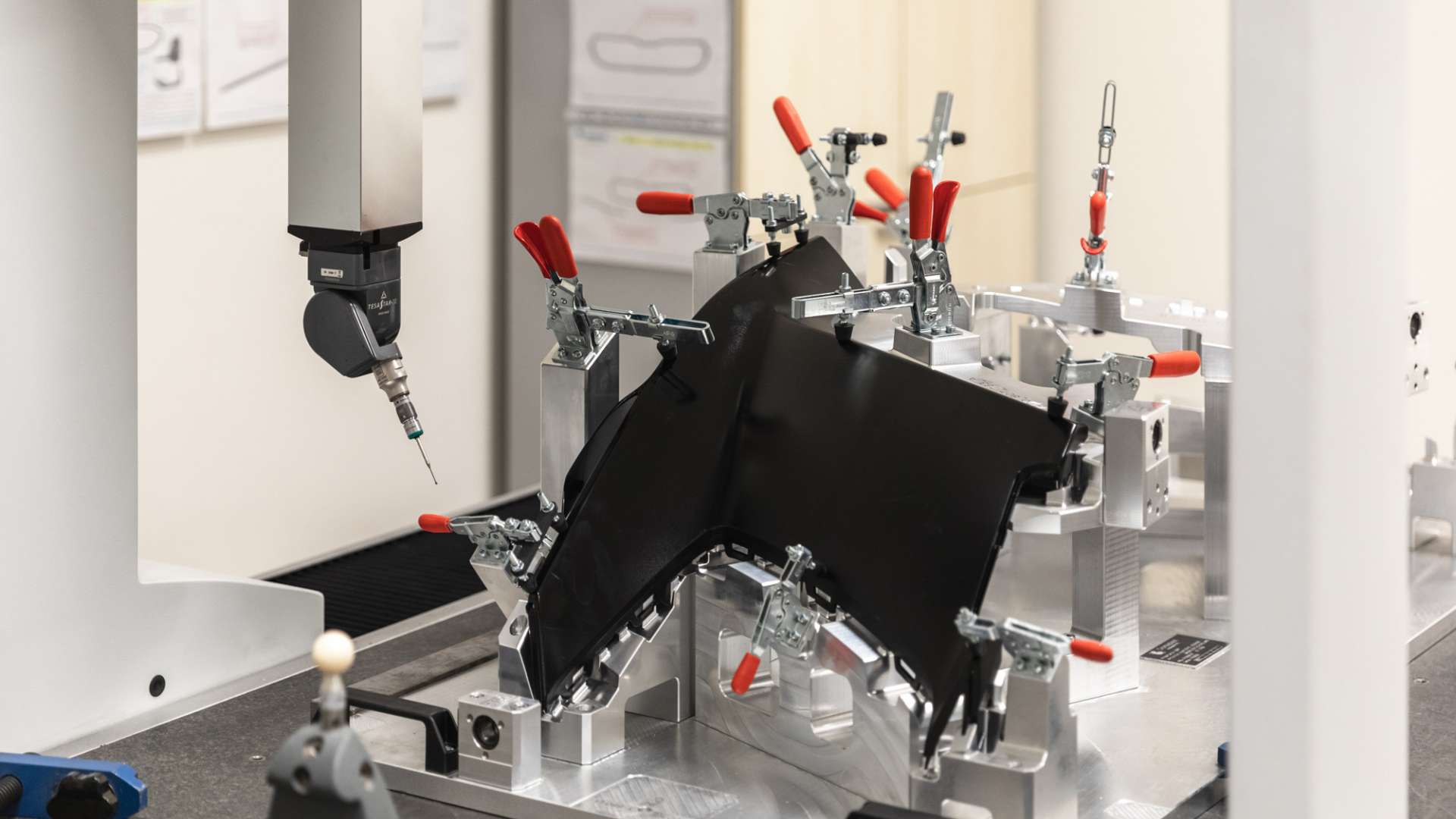

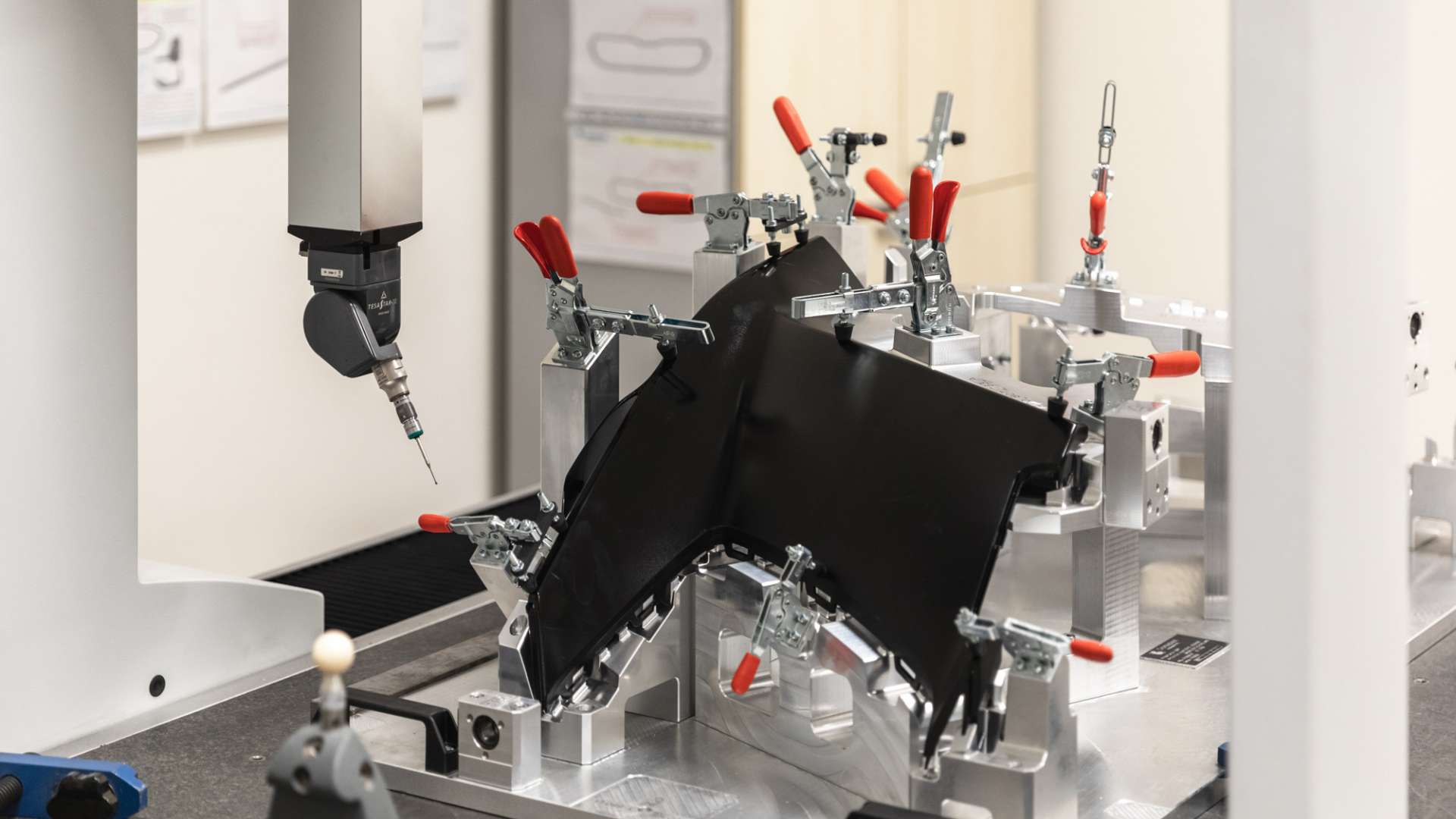

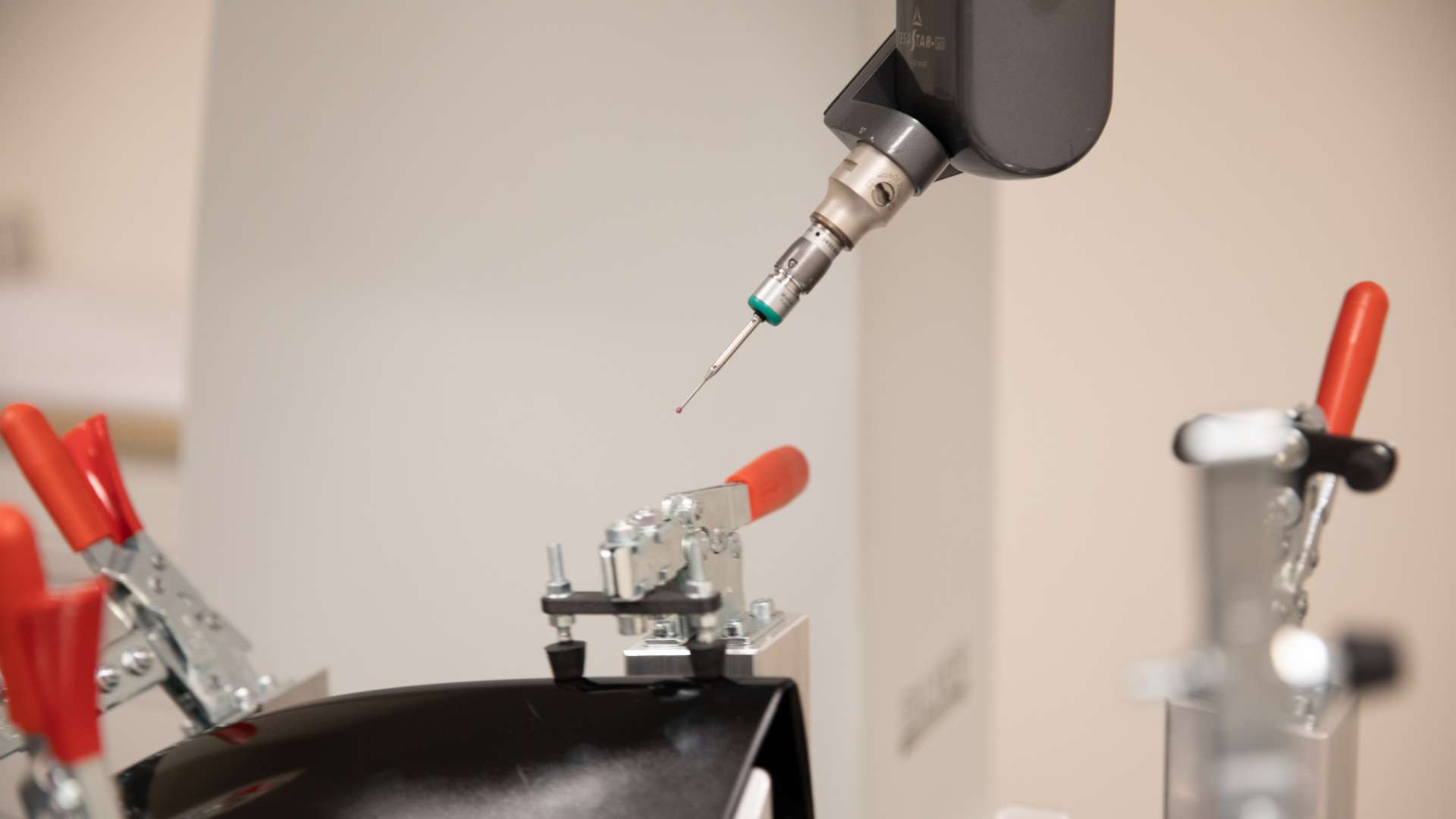

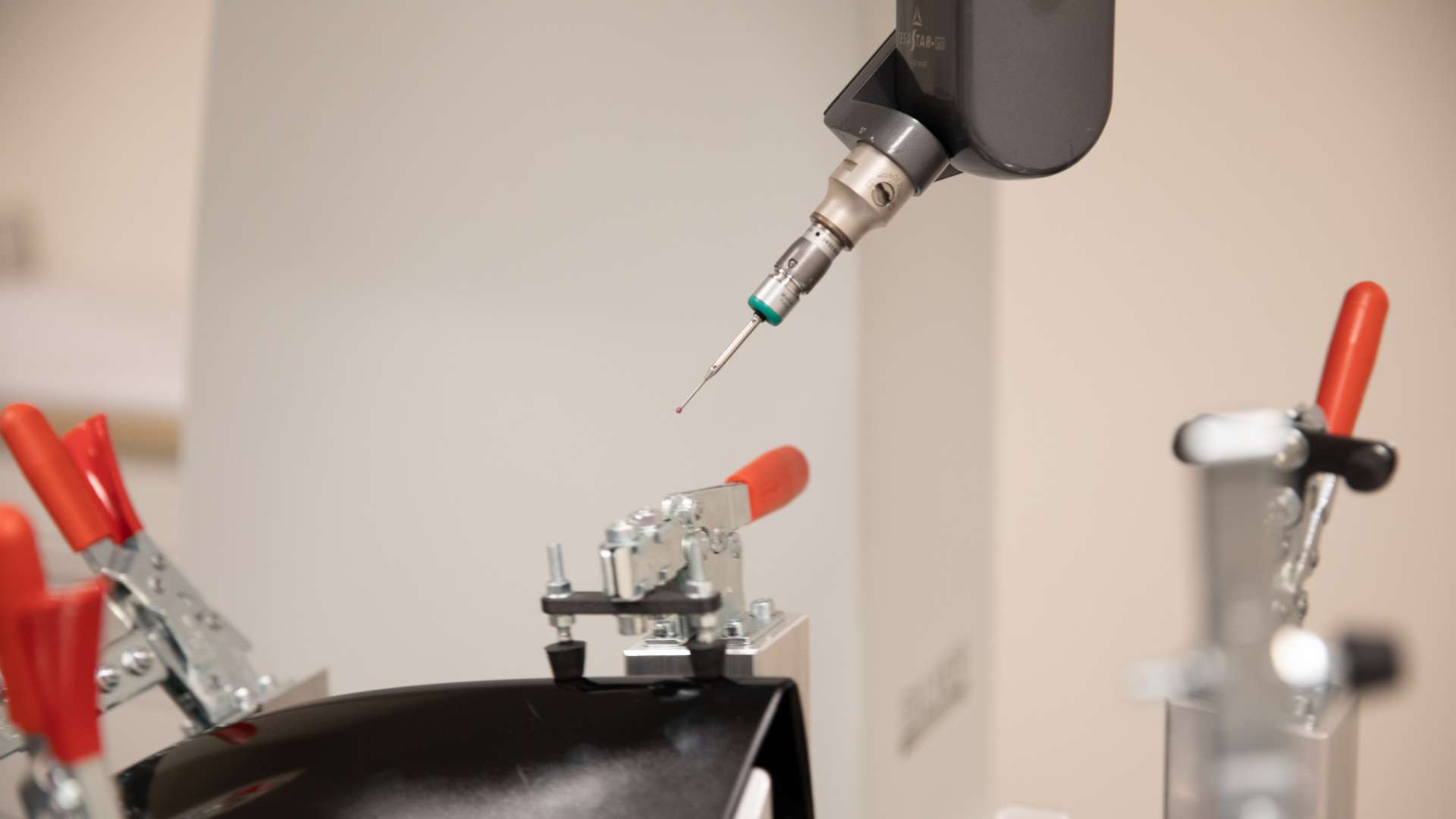

Our metrological analysis goes beyond the surface, using precision tools and advanced methodologies to ensure compliance with the highest standards. We measure and evaluate each component to ensure that every product meets specifications impeccably. The precision is our commitment, and your peace of mind is our priority.

Cromaplast is proud to have an accredited in-house testing laboratory dedicated to the control and verification of production processes. This allows us to ensure that every step of the process meets the highest standards of quality and reliability. The laboratory is equipped with advanced instrumentation to monitor and optimise performance, ensuring continuous improvement and customised solutions to meet the specific needs of our customers.

Accreditation ensures the competence and impartiality of our laboratory, which operates according to international standards. More information on accreditation can be found in the customer information sheet.

Are you young and talented seeking a stimulating challenge and an opportunity for professional growth?

Cromaplast S.p.A. is founded on the balance between innovation, operational excellence and collaboration